Jun. 13, 2023

Mechanical Parts

Introduction

In hydraulic systems, the use of hoses is crucial for the safe and efficient transfer of fluid power. Among the various types of hoses available, steel braided hydraulic hoses have gained immense popularity due to their strength, flexibility, and reliability. In this article, we will explore what steel braided hydraulic hoses are, their construction, advantages, applications, and the importance of proper installation and maintenance.

What is a Steel Braided Hydraulic Hose?

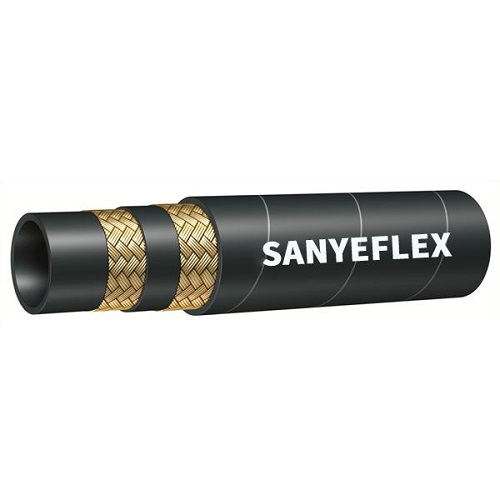

A steel braided hydraulic hose is a flexible tube designed to carry hydraulic fluids under high pressure. It consists of an inner tube, reinforcement layers, and an outer cover. The distinguishing feature of a steel braided hydraulic hose is the layer of steel wire braiding that provides additional strength and protection.

Construction of a Steel Braided Hydraulic Hose

A steel braided hydraulic hose typically consists of the following components:

Inner Tube: The inner tube is made of a synthetic rubber compound that is compatible with the hydraulic fluid being conveyed. It provides a smooth and consistent flow path for the fluid.

Reinforcement Layers: The reinforcement layers are typically made of high-tensile steel wires that are braided or spiraled around the inner tube. These layers provide structural strength and prevent the hose from bursting under high pressure.

Outer Cover: The outer cover is made of a synthetic rubber or thermoplastic material. It protects the reinforcement layers from abrasion, chemicals, and environmental factors. The outer cover also provides additional resistance to oil, ozone, and weathering.

Advantages of Steel Braided Hydraulic Hoses

Steel braided hydraulic hoses offer several advantages over other types of hoses:

Strength and Durability: The steel wire braiding provides exceptional strength, making the hose resistant to high pressure and mechanical stresses. It ensures the integrity of the hose even in demanding applications.

Flexibility: Despite their robust construction, Sanye steel braided hydraulic hoses remain flexible, allowing for easy installation and routing in tight spaces. This flexibility reduces the risk of hose failure due to kinks or bends.

Resistance to Abrasion: The outer cover of a steel braided hydraulic hose is designed to withstand abrasion from external factors, such as contact with rough surfaces or friction during operation. This extends the lifespan of the hose and reduces the need for frequent replacements.

Compatibility: Steel braided hydraulic hoses are compatible with a wide range of hydraulic fluids, including petroleum-based oils, synthetic oils, and water-based fluids. This versatility makes them suitable for various hydraulic applications.

Applications of Steel Braided Hydraulic Hoses

Steel braided hydraulic hoses find extensive use in numerous industries and applications, including:

Construction: Steel braided hydraulic hoses are used in construction machinery, such as excavators, loaders, and cranes, for hydraulic power transmission and control.

Agriculture: Agricultural machinery, including tractors, harvesters, and sprayers, rely on steel braided hydraulic hoses for efficient operation of hydraulic systems used for lifting, steering, and control.

Manufacturing: Steel braided hydraulic hoses are essential in manufacturing processes that involve hydraulic equipment, such as presses, injection molding machines, and material handling systems.

Transportation: Vehicles, including trucks, buses, and off-road vehicles, utilize steel braided hydraulic hoses in braking systems, suspension systems, and power steering systems.

Mining: In mining operations, steel braided hydraulic hoses are used in equipment like hydraulic excavators, drill rigs, and underground mining machinery, where reliable hydraulic power transmission is critical.

Proper Installation and Maintenance

To ensure the optimal performance and longevity of steel braided hydraulic hoses, proper installation and maintenance practices are essential. Here are some key considerations:

Correct Assembly: Follow the manufacturer's instructions for assembling and crimping the hose fittings. Improper assembly can result in leaks, hose failure, or compromised performance.

Inspect Regularly: Perform visual inspections of the hose for signs of wear, damage, or leakage. Replace any hoses that show signs of deterioration or damage.

Prevent Twisting and Kinking: Avoid excessive twisting or kinking of the hose during installation or operation, as it can weaken the hose and lead to failure.

Follow Operating Parameters: Operate the hydraulic system within the specified temperature and pressure limits to prevent excessive stress on the hose.

Replace as Recommended: Replace steel braided hydraulic hoses as recommended by the manufacturer or based on the operating hours or service life specified for the hose.

Conclusion

Steel braided hydraulic hoses offer a reliable and robust solution for hydraulic power transmission in various industries. With their strength, flexibility, and resistance to abrasion, these hoses ensure efficient fluid power transfer and provide long-lasting performance. Proper installation, regular maintenance, and adherence to operating parameters are crucial for maximizing the lifespan and performance of steel braided hydraulic hoses. When choosing hoses for hydraulic systems, the strength and reliability of steel braided hydraulic hoses make them a preferred choice.

Frequently Asked Questions (FAQs)

Q1: Can steel braided hydraulic hoses handle high-pressure applications?

Yes, steel braided hydraulic hoses are designed to withstand high-pressure conditions and provide reliable performance in demanding hydraulic systems.

Q2: Are steel braided hydraulic hoses China compatible with all hydraulic fluids?

Steel braided hydraulic hoses are compatible with a wide range of hydraulic fluids, but it is important to check the compatibility with the specific fluid being used to ensure optimal performance and longevity.

Q3: Can steel braided hydraulic hoses be repaired if damaged?

In general, it is recommended to replace damaged steel braided hydraulic hoses rather than attempting to repair them. Proper crimping and assembly of hose fittings are critical to ensure the integrity and safety of the hydraulic system.

Q4: Can steel braided hydraulic hoses be used in high-temperature environments?

Steel braided hydraulic hoses are designed to withstand a certain range of temperatures. It is important to select hoses that are rated for the intended operating temperature of the hydraulic system to avoid hose degradation or failure.

Q5: How often should steel braided hydraulic hoses be replaced?

The replacement interval for steel braided hydraulic hoses depends on various factors such as operating conditions, application, and manufacturer recommendations. Regular inspections and proactive replacement based on visual wear or specified service life are recommended to ensure optimal performance and safety.

Previous: What are the main three functions of a directional control valve in a hydraulic circuit?

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )