Feb. 22, 2024

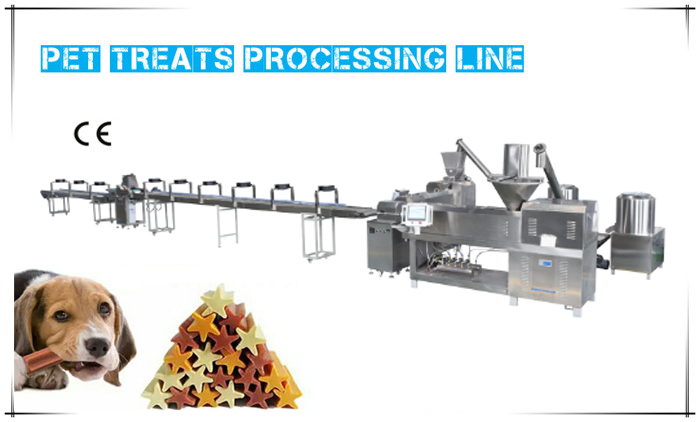

Pet treat extrusion lines are essential equipment for producing high-quality treats for our furry friends. Proper maintenance ensures optimal performance and longevity of the equipment. In this guide, we'll walk you through step-by-step on how to maintain your pet treats extrusion line effectively.

Regularly inspect the extruder screws for any signs of wear or damage. Look out for worn-out or broken sections that may affect the quality of the treats.

Ensure that the temperature control system is functioning correctly. Verify that the temperatures are consistent throughout the extrusion process to achieve uniform treat quality.

Regularly clean the extruder barrel to remove any residue or buildup. Use a suitable cleaning solution and follow manufacturer guidelines to prevent contamination and ensure product safety.

Check for any blockages in the extrusion line, including the die and nozzles. Clear any obstructions to maintain smooth product flow and prevent equipment damage.

Apply lubricant to all moving parts of the extrusion line, including gears, bearings, and rollers. Lubrication reduces friction, extends component lifespan, and ensures smooth operation.

Check seals and gaskets for signs of wear or leaks. Replace any damaged seals to prevent ingredient leakage and maintain food safety standards.

Regularly calibrate the equipment settings to ensure precise control over the extrusion process. Adjust parameters such as screw speed, temperature, and pressure according to product specifications.

Continuously monitor the quality of the produced treats during operation. Make adjustments to the equipment settings as needed to maintain consistent product quality and meet customer expectations.

Train operators on proper operating procedures and maintenance protocols for the extrusion line. Emphasize the importance of regular maintenance and adherence to safety guidelines.

Keep detailed records of maintenance activities, including inspections, cleanings, and repairs. Documenting maintenance procedures allows for easier troubleshooting and helps identify any recurring issues.

Regular maintenance is crucial for ensuring the efficient operation of your pet treats extrusion line. By following these step-by-step guidelines, you can prolong the lifespan of your Pet Food Machine, minimize downtime, and continue delivering high-quality treats to your furry companions.

Previous: None

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )