Apr. 03, 2024

Machinery

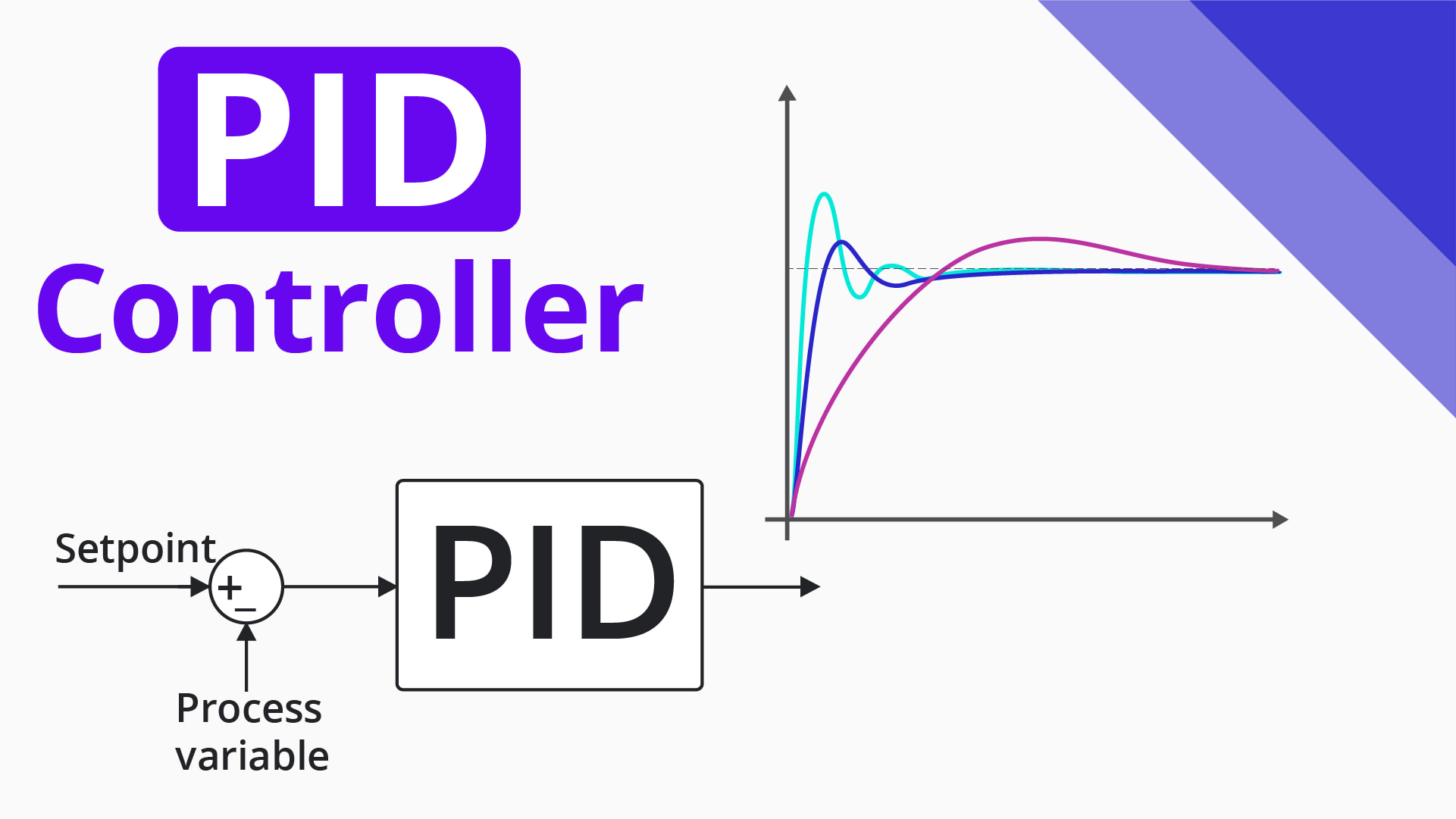

There are three parameters P, I, and D in PID control. Only by understanding the meaning and function of these three parameters can the controller PID parameter tuning be completed and the controller achieve the best control effect. Being able to skillfully tune PID parameters and put the automatic control system into automatic mode represents the automation skill level of engineering and technical personnel, but many people do not really master PID control and PID parameter tuning.

The proportional controller is actually an amplifier with adjustable amplification, that is, △P=Kp×e, where Kp is the proportional gain, that is, Kp can be greater than 1 or less than 1; e is the input of the controller, which is the measurement The difference between a value and a given value is also called the deviation.

It should be noted that for most analog controllers, the proportional gain Kp is not used as the scale, but the proportion is used as the scale, that is, δ=1/Kc×100%. That is to say, the proportion is proportional to the reciprocal of the controller's amplification factor; the smaller the controller's proportion, the greater its amplification factor and the greater its ability to amplify deviations, and vice versa.

Understand the above relationship, you can know: the greater the proportion, the smaller the amplification factor of the controller, the more stable the curve of the controlled parameter; the smaller the proportion, the greater the amplification factor of the controller, the more fluctuating the curve of the controlled parameter. .

Proportional control has a disadvantage, that is, it will produce residuals. To overcome the residuals, integral action must be introduced.

The integral function of the controller is set up to eliminate the residual error of the automatic control system. The so-called integration means accumulation over time, that is, when there is a deviation input e, the integral controller will continuously accumulate the deviation over time, that is, the speed of integration accumulation is proportional to the size of the deviation e and the integration speed. As long as the deviation e exists, the output of the integral controller will change, which means that the integration will always work. The integration will stop only when the deviation does not exist.

For a constant deviation, the essence of adjusting the integral action is to change the rate of change of the controller output. This rate is measured by the period of time required for the output of the integral action to equal the output of the proportional action. If the integration time is small, it means that the integration speed is large, and the integral effect is strong; conversely, if the integration time is long, the integral effect is weak. If the integral time is infinite, it means there is no integral effect and the controller becomes a pure proportional controller.

In fact, the integral action is rarely used alone, and is usually used together with the proportional action, so that it has both the proportional action of amplifying (or reducing) the deviation and the integral action of accumulating the deviation over time, and its direction of action is consistent. At this time, the output of the controller is: △P=Ke+△Pi, where △P is the change in the output value of the controller; Ke is the output caused by the proportional action; △Pi is the output caused by the integral action.

The differential effect is mainly used to overcome the hysteresis of the controlled object and is often used in temperature control systems. In addition to using differential action, when using the control system, attention should be paid to the lag problem of measurement transmission, such as the selection and installation position of the temperature measurement element.

In a conventional PID controller, the output change of the differential action is proportional to the differential time and the speed of the deviation change, and has nothing to do with the size of the deviation. The greater the speed of the deviation change and the longer the differential time, the greater the change in the output of the differential action. . However, if the differential effect is too strong, it may cause oscillation by itself due to too rapid changes, causing obvious "peaks" or "jumps" in the controller output.

In order to avoid this disturbance, the differential-first PID operation rule can be used in the PID regulator and DCS, that is, only the measured value PV is differentiated. When the given value SP of the controller is artificially changed, it will not cause a sudden change in the controller output. , to avoid the disturbance caused to the control system at the moment of changing SP. For example, TDC-3000 adds a soft switch to the conventional PID algorithm. During configuration, the user can choose whether the controller differentiates the deviation or the measured value.

When a step signal is input, the ratio of the maximum change value of the differentiator output at the beginning and the output change after the differential effect disappears is the differential amplification factor Kd, that is, the differential gain. The unit of differential gain is time. Set the differential time (or differential gain ) being zero will cancel the differential function.

Previous: How are battery packs assembled?

Next: Maximize Efficiency with Automatic Profile Wrapping Machine

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )