May. 25, 2023

Machinery

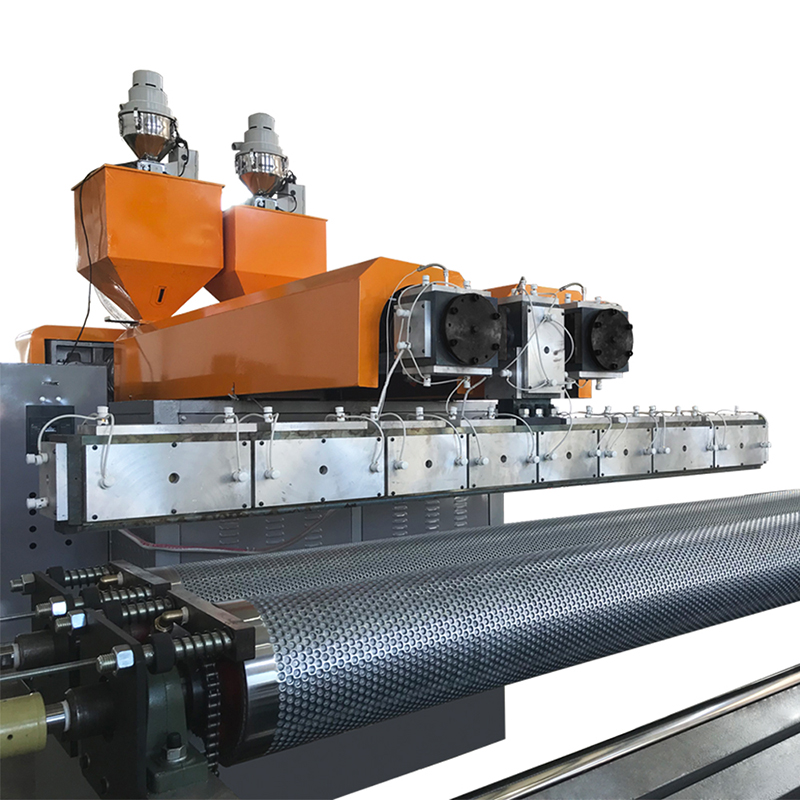

In today's fast-paced world, the packaging industry plays a crucial role in ensuring the safe transportation and protection of products. One technology that has revolutionized the packaging sector is the air bubble film extrusion machine. This innovative machine is responsible for the production of air bubble film, a versatile and effective packaging material known for its cushioning and protective properties.

The air bubble film extrusion machine utilizes the extrusion process to create a continuous sheet of air bubble film. The process starts with the feeding of raw materials, typically LDPE (Low-Density Polyethylene) or HDPE (High-Density Polyethylene) resin, into the extruder. The resin is melted and then forced through a die, which shapes the molten plastic into a long tube with air bubbles trapped between two layers of film.

The trapped air bubbles in the film are the key to its protective properties. The bubbles act as cushions, absorbing shocks and impacts during transportation and handling. This makes air bubble film an ideal packaging material for fragile and delicate items, such as electronics, glassware, ceramics, and automotive parts.

The air bubble film extrusion machine offers several advantages over traditional packaging materials. Firstly, it provides excellent protection against scratches, dents, and breakage. The air bubbles create a barrier between the product and the external environment, preventing direct contact and minimizing the risk of damage. This is particularly important when products are subjected to rough handling or long-distance transportation.

Secondly, air bubble film is lightweight and flexible, which helps reduce packaging costs and improve operational efficiency. It can be easily cut, folded, and customized to fit various shapes and sizes of products. This versatility makes it suitable for packaging items of different dimensions, eliminating the need for excessive packaging materials.

Another significant advantage of air bubble film is its transparency. Unlike opaque packaging materials, the clear film allows for easy identification and visual inspection of the packaged product. This is particularly important in industries where product visibility is crucial, such as retail and e-commerce.

Furthermore, air bubble film is recyclable and environmentally friendly. Many manufacturers produce air bubble film using recycled plastic materials, contributing to the reduction of plastic waste and the conservation of resources. Additionally, the lightweight nature of the film helps reduce carbon emissions during transportation, further supporting sustainable practices in the packaging industry.

The Multi-Layers air bubble film extrusion machine also offers high production efficiency. It is capable of producing a continuous roll of air bubble film at a fast rate, allowing for large-scale production and quick turnaround times. The automation of the machine ensures consistent quality and reduces the reliance on manual labor, leading to increased productivity and cost savings for manufacturers.

In conclusion, the air bubble film extrusion machine has transformed the packaging industry by providing innovative and efficient solutions for product protection. Its ability to produce air bubble film with cushioning and protective properties has made it an essential component of packaging systems across various industries. From fragile electronic devices to delicate glassware, air bubble film offers reliable and cost-effective packaging solutions. As the demand for secure and sustainable packaging continues to rise, the air bubble film extrusion machine will play a vital role in meeting the evolving needs of the market.

Suggested reading:

More articles:

Choosing the Right Bottle Bagging Machine for Your Packaging Needs

Horizontal Flow Wrap Machine: Enhancing Packaging Efficiency and Productivity

What is a spout pouch packing machine used for?

EPS Shape Moulding Machine: Shaping the Future of Packaging and Construction

Previous: Enhancing Safety and Quality Control: The Glove Leak Detection Machine

Next: Exploring the Secrets of Artificial Rice and Instant Noodle Processing Lines

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )